Spraying is ever present in our lives, and has been used for ages for a number of purposes, including applying decorative and protective coatings. Thus it is another tool available to a Material Scientist for thin film preparation.

In spray coating, the nozzle dimension, the spray shape, nozzle to substrate distance, spray velocity and application of heat to the substrate during spraying are parameters that can be controlled for optimum result. These are accomplished easily in the MultiCoater, and more.

Pressure nozzles were initially used in spray coating. They have the set back of requiring slightly complex system (for pressure generation), high material wastage and environmental pollution, especially dangerous for the personnel doing the spraying.

Benefits

-

Small homogeneous droplets

-

Control over droplet size

-

Micro volumes can be dispensed

-

Changeable syringes

-

More than one independently driven syringe option

-

Nozzle adjustable by up to 180 °

Ultrasonic spray coating

Multi-utilized atomization system

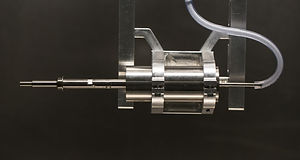

With ultrasonic nozzle, the spray solution is homogenised, drop size effectively controlled (nozzle frequency influences drop size), and micro spray volumes can be dispensed, ensuring uniformity in composition and structure and more precision of the resultant thin films and patterns. Material wastage is kept to a minimum and there is less risk to the operator of the equipment.

The MultiCoater’s ultrasonic spray coater can be equipped with a heated platform for the substrate, e.g. a hot plate. More than one independently controlled syringes (coating solution container) can be used to handle different materials, essential for multilayer fabrication or creating different thin films on different parts of a substrate - if necessary one of the syringes can contain a cleaning liquid, e.g distilled water, to avoid contamination. The ultrasonic spray coater can be combined with a dip coater, in this situation being kept stationary while the dip coating module is mobile

|

|---|

|

|

|

|

|

|

The nozzle can be tilted 90 degrees in each direction to allow for both horizontal and vertical spray coating

Applications

-

Fuel cells

-

Membranes

-

Gass separation

-

Transparent conductive film

-

Photoresist on MEMs wafer

-

Protective coatings, etc